For this blog, i will be showcasing my journey on how I design an handphone stand to be laser cut

I was tasked to design a handphone stand using parametrics.

from my research, my understanding of a parametic design is system that allows users to easily change the dimensions of a finished sketch to suit their needs. for example, different material that is provided for the laser cutter have different dimensions. if I already designed my handphone stand for a specific thickness of material, I can use parametric design to help me change the dimensions of my handphone stand without redesigning the whole handphone stand.

before sketching my design, I went online to look for some inspiration. i found that for laser cutting to be most viable, I used to slab of material and slot them into each other to create a stand.

Here is my sketch I created to help me visualise my design.

After I had a rough idea of how my handphone stand would look like, i used the fusion 360 software to create a 3d design of my phone stand.

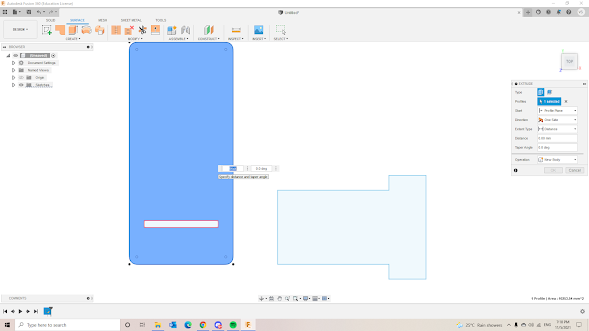

I first created a base sketch of my phone stand. since i planned to use parametric to help in my phone stand, i created a user parameter naming it thickness to account for the various material thickness that might be available for laser cutting.

After creating the main shape for the handphone stand, i created a slot in the right shape with dimension similar to the left shape to slide in. The slot dimensions was linked to the thickness of the material.

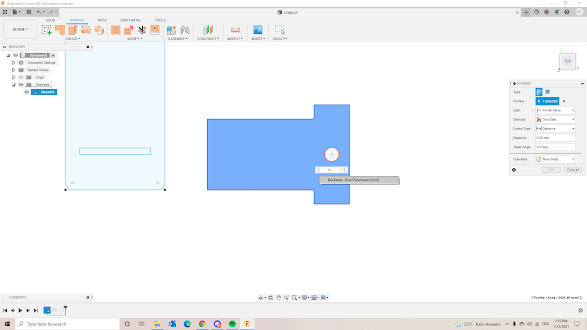

i then extrude both shapes with the dimensions as 'thickness'. meanwhile i created a hole to allow the phone to be charged while on the stand.

After extruding the shapes, i was basically done.

here is an image to show how the parametric would work. If the material provided is 10mm thick, i can easily change by going into the change parameter setting and changing the expression.

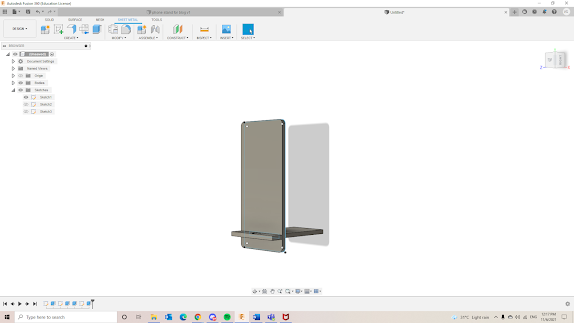

This is how the handphone stand would look like after slotting the two parts together. when placed on a flat surface, the phone stand would be leaning slightly.

And that's it, the completed handphone design.

Have a look at my handphone stand below